Nondestructive Testing (NDT) is an approach to evaluating products or materials, that doesn’t require their disassembly or otherwise impair their functionality. NDT can employ magnetics, ultrasound, x-rays, and other technologies. Art+Logic has worked on a variety of NDT-related projects. The brief interview that follows, addresses some of the more common questions about NDT.

Andrew: Hi Bob. So let’s start out with me asking you, who does nondestructive testing? Is that something I could just jump into?

Bob: No, there are specially certified NDT experts who design the techniques and do the testing, and there are three levels of certification.

Level I technicians are trained to perform the inspections. They understand how the sensors work, how they interact with the material being tested, that sort of thing. The training work involves principles of physics and trigonometry; angles of incidence and reflection, for example. A level I inspector must be proficient at carrying out written instructions.

A Level II certification allows the engineer to perform more complicated testing, supervise the Level I engineers, and even design the hardware used for performing the tests. You don’t technically need to be Level II certified to design the equipment. Level certifications are more about how much of the inspection can you do. Just follow the instructions, or calibrate the equipment and interpret results, or actually design the techniques and document the procedures. Leve II engineers have a deeper understanding of the process. I was certified at Level II a number of years ago. Level II operators can calibrate equipment, evaluate results and produce reports.

Level III training provides the skills needed to design and document the actual tests.

Also, these levels apply to specific disciplines. Level III in Ultrasonics doesn’t translate to testing with X-Rays, Eddy Current Testing, Particle Testing, etc. It’s kind of like how being a great guitarist doesn’t help you play baseball.

Andrew: Funny you mention that because I’m a big fan of Bernie Williams; the Yankee’s center fielder who was nominated for a Latin Grammy for his guitar work!

So there are a lot of kinds of testing?

Bob: Definitely. Just in ultrasonics, there’s Pulse Echo and Through Transmission methods, Single Element and Dual Element probes, Thickness Testing, Velocity Testing, and lots more.

Andrew: Any good stories from the testing trenches?

Bob: Sure… Once, Ben & Jerry’s sent us a ton of ice cream, packed in freezer containers, and they wanted to know if there was a way to measure the number of chunks in each carton for quality control.

Andrew: Was there?

Bob: Unfortunately, in that case, we didn’t find a way. The ice crystals in the product dispersed the sound waves too much, so we couldn’t get consistent readings. We ate the ice cream instead.

There’s a similar example that worked well, though, and in fact, it relied on that inability for sound to pass through the test material. Baby formula needs to be kept for a month, prior to shipment. This gives it enough time to spoil if it’s been improperly sealed. But then how do you test for that spoilage? It turns out that the consistency of the formula changes in such a way that sound doesn’t pass through spoiled formula. If sound passes through, the sample is good! It’s not the only test they used; they would still pull some percentage for manual inspection and verification, and that’s standard practice in testing. For example, some percentage of brake calipers will be cut open and inspected for appropriate “nodularity” under a microscope to ensure they’re not too brittle. That would be considered a form of destructive testing.

Andrew: So what kinds of people come to us for custom software help in the NDT world?

Bob: Well, I worked at Krautkramer Branson before A+L, a company that makes testing hardware (transducers, instrumentation, etc.), and at the time was one of the industry’s leaders. Their team was fully occupied developing their hardware products. I came in to oversee their “Custom Systems Group.” The plan was for us to create a custom solution that was unique to each installation. I realized it would be possible to write a more general purpose system that could be quickly adapted to each installation. This is an approach Art+Logic has since taken with other clients in NDT. There are advantages for a client to support their hardware in a more general manner like this: first, after the initial investment, deployments are much less expensive. Also, if you’re only doing larger installations you might have the margin to support writing custom software every time, but having a reusable system opens up your market to smaller to medium-sized end-users too.

Andrew: So are most of our NDT clients the hardware manufacturers?

Bob: There are really a couple of types of clients. The first is what you describe; an equipment manufacturer and vendor. As an example, our Ultraproof project, written for the hardware manufacturer, was part of a testing machine. It was designed to collect and analyze data, pass or fail the part, then control the hardware with digital signals to weed out those bad parts, like maybe sending the bad ones to one location, and the good parts to another destination using gates andconveyor belts.

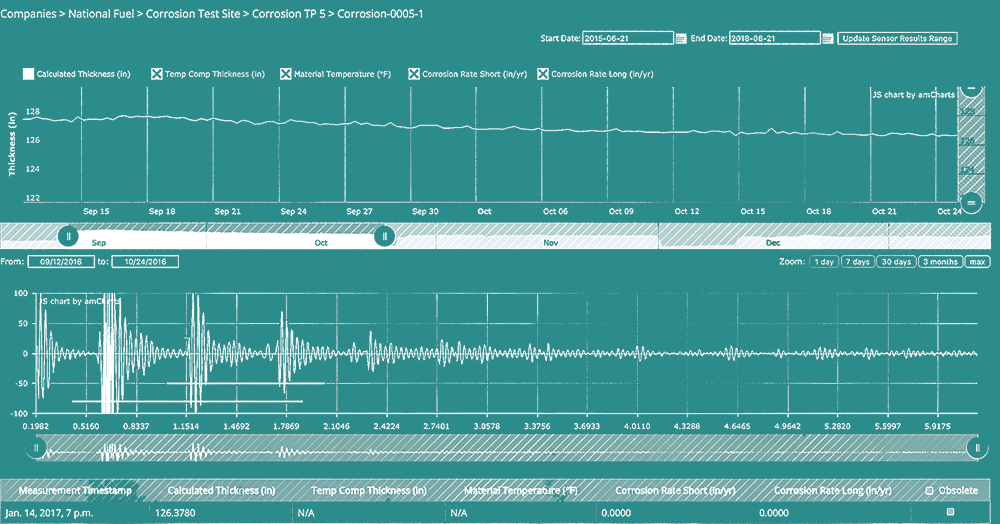

Then again the Sensor Networks’ project is more about capturing data over time, analyzing it, detecting trends, and recommending action. This can be wise to outsource because it’s less about basic operations of the hardware and more customized to a specific (and possibly niche) application of the product. You could take the same product and do something completely different with it – the product is just a sensor that measures thickness and has no idea what to do with that information. It could be used in a manufacturing process, or ongoing monitoring as it was in this case. This sort of project is often undertaken by the end-users who want to develop a specialized solution, using the hardware, in their specific industry. In many cases, they might be able to resell the solution to other users in the same industry, of course.

Spot the Vulnerability: Loops and Terminating Conditions

Spot the Vulnerability: Loops and Terminating Conditions In memory-unsafe languages like C, special care must be taken when copying untrusted data, particularly when copying it to another buffer. In this post, we\'ll spot and mitigate a past vulnerability in Linux\'s...